.JPG) |

With the slope of the hull and the web

supporting the aft lower shroud fitting

there is not a lot of room behind the toilet

and none under. Securing a sometimes

heavy tank would also be difficult. |

To be more environmentally friendly and to avoid some trips ashore for "comfort breaks", I have been toying with the idea of a black water holding tank for several years but its not easy because of space constraints.

Older boats are not required to have holding tanks in most jurisdictions, regulations vary by country but generally waste can be discharged when more than 3 miles offshore, perhaps unsurprisingly (in 2023) there are no restrictions on discharging waste in UK coastal waters although many marinas and harbours have local regulations or by-laws banning discharges.

The space behind the toilet could take a tank but to be anywhere near a useful size it would have to be bespoke and therefore very expensive, it would also be difficult to fit to the sloping hull, difficult to plumb in and I would loose some small but handy storage space for toiletries and loo cleaner.

Underneath what was the port berth in the forepeak or under the port berth in the saloon would both easily take a rubber tank but they are difficult to secure and I don't fancy a rubber tank full of sewage anywhere in the boat. Again solid tanks would have to be specially made and both options would require lots of expensive plumbing with diverter valves, pump, etc..

More realistically with the forepeak no longer having berths, a tank could be installed there on the port bulkhead next to the heads.

If the tank bottom is high enough above the waterline and the pipe work reasonably short and not too bendy this could be emptied overboard by gravity and, with the appropriate fittings, optionally by pump out.

Again space and cost are issues; an excellent vertical tank is made by "Tek-Tanks" it is made to order in standard sizes with inlets and outlets positioned to order. There are problems, space is at best barely adequate for the smallest 40 litre version, there might not be sufficient "head" for it to drain correctly, and the tank without hose tails is £389. A similar but much cruder design by Nuova Rade is only £159 but again it would be difficult to fit and drainage could be an issue. Both options could be made to work with a lot of plumbing and a pump to drain the tank as sea but it gets expensive and complicated.

|

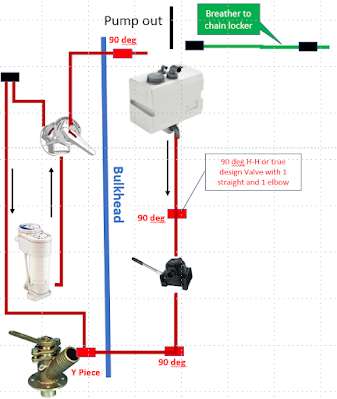

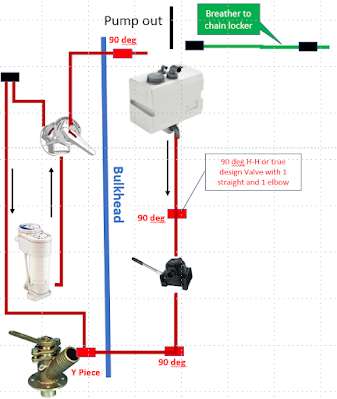

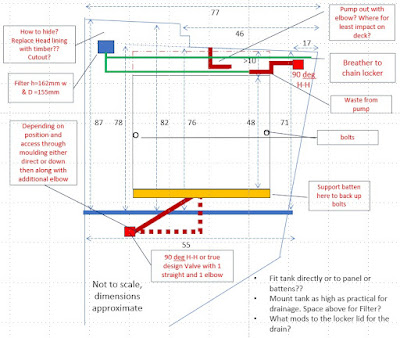

| Schematic of the planned installation. |

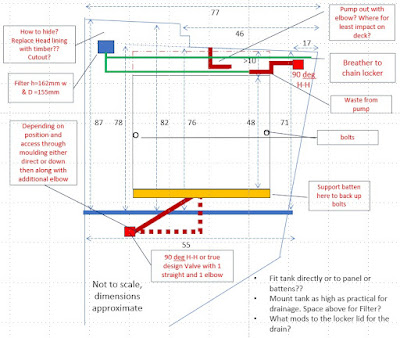

I gave up on the project the last couple of winters but this year I found a 25 litre horizontally orientated tank by Vetus that is much shallower so gives more space for installation above and below and a better head for drainage, still £270 but unlike the other tanks that does included all the hose tails bar one.

The height for gravity drainage looks to be OK even if a couple of elbows are required, especially as the electric pump and Macerator does a better job of breaking up solids and paper than a manually operated toilet.

When offshore the seacock is left open and waste goes straight out, in sensitive areas the sea cock is closed and the waste accumulates in the holding tank later be released at sea or pumped out.

If in use the gravity drainage proves not to work there is room to install the new Henderson Mk5 pump I happen to have (its a long story) between the tank and the seacock. That would be a pain at sea requiring manual pump outs but it would work and I could add a diverter valve and additional pipe work.

|

| The back up plan (see next post for an updated final version). |

|

| Outline plan for the bulkhead mount. |

Most of the components are on order and should be here by early next week, the rest I'll get locally some after trial fits, and I'll start the installation when there is some decent weather to visit the boat.

.JPG)

.JPG)

.JPG)

.JPG)

%20pan.jpg)

%20crop.jpg)

.JPG)

.JPG)

.JPG)